Description

Basic Information

| Grinder Type | Metal, Ceramics Flat Surface | Automatic Grade | Automatic |

| Certification | CE, ISO 9001 | Precision | High Precision |

| Table Size | 250*600mm | Condition | New |

| Total Power | 5kw | Floor Space | 1900*2400mm |

| Cross Feed Motor | Siemens Servo Motor | Vertical Motor | Siemens Servo Motor |

| Vertical Screw | P4 Grade Ball Screw | Cross Feed Screw | Ball Screw |

| PLC Brand | Siemens PLC | XMovement | Hydraulic |

| Spindle Bearing | NSK P4 Grade | Spindle Motor | ABB/Siemens |

| Transport Package | Wooden Case | Main Electrics | Schneider Electrics |

| Origin | China | Specification | 1960*1560*2140 |

| Trademark | ZODE | HS Code | 8460191000 |

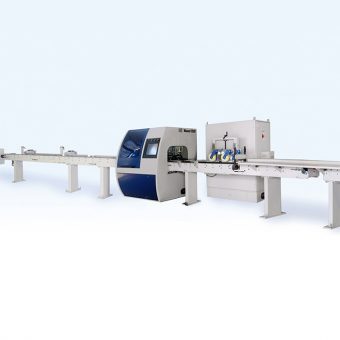

Product Description

A.Pictures

Control Panel:

(S Model Control Panel)

(SD Control Panel)

SD SERIES PROGRAMMING CYCLE

S stands for simple program control, three-axis automatic, longitudinal hydraulic drive, cross feed and vertical axes are driven by servo motors.

(Automatic down feed, the minimum down feed is 0.002mm, and there is an automatic lifting function).

SD stands for high configuration program control, three-axis automatic, longitudinal hydraulic drive,cross feed and vertical axes are driven by servo motors, and equipped with touch screen to set parameters.

(Automatic down feed, the minimum down feed is 0.001mm, and has the functions of rough grinding, fine grinding, automatic lifting and spark out grinding).

(The SD series can add optional features: the X-axis position can be displayed on the touch screen and its travel can be controlled.)

B.Parameters

| Parameters | Unit | SG2560S | SG2560SD | |

| Working Surface of Table | mm | 255*600 (10"*24") | 255*600 (10"*24") | |

| Max.Table Travel | mm | 660 | 660 | |

| Max.Cross Travel | mm | 280 | 280 | |

| Distance Between Table Surface and Spindle Center | mm | 535 | 535 | |

| Max.Table Load | kgs | 300 | 300 | |

| T-Solt(Number*Width) | mm | 1*14 | 1*14 | |

| Table Speed | m/min | 5~25 | 5~25 | |

| Crossfeed Handwheel | 1gard | mm | 0.02 | 0.02 |

| 1 rev | 5 | 5 | ||

| Automatic Crossfeed of Saddle | mm | 0.01~12 | 0.01~12 | |

| Automatic Crossfeed Rate | mm/min | 10~800 | 10~800 | |

| Power Cross Feed | mm/min | 1500 | 1500 | |

| Grinding Wheel Dimensions | mm | 200*25*32/31.75 | 200*25*32/31.75 | |

| Spindle Speed | 50HZ | rpm | 2850 | 2850 |

| 60HZ | 3420 | 3420 | ||

| Vertical Handwheel | 1gard | mm | 0.001 | 0.001 |

| 1 rev | 0.5 | 0.1 | ||

| Automatic Down Feed Rate | mm | 0.002/0.004/0.006/0.012/0.02/0.03/0.04/0.05 | 0.001~0.1 | |

| Power Head Increment | mm/min | 400 | 1000 | |

| Spindle Motor | kw | 2.2 | 2.2 | |

| Floor Space | mm | 1900*2400 | 1900*2400 | |

| Packing Dimensions | mm | 1960*1560*2140 | 2100x1840x2200 | |

| Net Weight | kgs | 1730 | 1730 | |

| Gross Weight | kgs | 1980 | 1980 | |

C.Standard Accessories

| 1 | Grinding wheel | 2 | Wheel flange |

| 3 | Wheel balancing base | 4 | Wheel balancing arbor |

| 5 | Extractor | 6 | Diamond dresser |

| 7 | Leveling pad | 8 | Anchor bolt |

| 9 | Tool box with tools | 10 | Electricmagneticchuck |

D.Feature

1.Well designed cast iron structure provides excellent dampening

2.Flange mount spindle cartridge for superior side grinding rigidity

3.Grinding spindle features low-maintenance preloaded high precision angular ball bearings (NSK P4 grade)

4."V" and flat type guide way which precision hand scrapped turcite saddle ways for smooth and long lasting performance

5.Table guideways are hardened, ground and counter-laminated with PTFE (TEFLON) to ensure high wear-resistance

6.Centralized automatic lubrication system, supplies oil to guide-ways and lead-screws as the machine operates. This system ensures all the critical components are lubricated with the right amount of oil at all times

7.Separate hydraulic tank prevents heat and vibrations from being transferred to the machine

8.Electric components and functional modules are well arranged and packed in the electric cabinet, making maintenance and trouble-shooting easily accessible

9.Safety 24V control circuit power

E.Application:

Applicable to all kinds of processing machinery, auto parts, fixture, magnetic steel, mould parts processing industry.

The machine tool can be made of grinding steel, iron, ceramics and non-ferrous metal parts.

Main Configuration of Grinding Machine

Ⅰ.Spindle motor: Use ABB brand which from Sweden.

Ⅱ.Spindle bearing: Use NSK brand P4 grade precision ball bearing which from Japan.

Ⅲ.Cross and vertical screw: Use P3/P2 grade precision ball screw.

Ⅳ.Main electrical components: Use SCHNEIDER brand.

Ⅴ.Main hydraulic components: Use brand from TAIWAN.

Ⅵ.Cross feed and down feed servo motor: Use SIEMENS brand.

F.Company & Factory

Nantong ZODE Machinery Manufacturing Co., Ltd. is a manufacturer engaged in the research and development, production, sales and service of CNC grinding machine equipment. The company adheres to the advanced production technology and technology in cooperation with Germany, and is committed to building a domestic high-quality grinding machine manufacturer. The company has an excellent R&D team, which serves precision grinding and can provide low-cost and high-efficiency solutions according to the actual grinding requirements of customers.

ZODE Machinery has a huge distribution channel, and its products are sold all over the world. With "quality is the foundation, service is the foundation", it has won the trust and cooperation of global customers.

In the future, ZODE people will continue to devote themselves to professional grinding solution providers and work together with partners to meet the ever-changing new challenges.

G.Delivery Picture

H.FAQ

Q: Are you trading company or manufacture?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 10~20 days if the goods are in stock. Or it is 30~60 days if the goods are not in stock, according to your quantity.

Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample, but need extra cost.

Q: What is your terms or payment?

A: 30%T/T in advance, balance before shippment.

Reviews

There are no reviews yet.